7 Signs You’re Due for Power Tool Repairs

Power tool repairs are essential for tradespeople and DIY enthusiasts. Whether you’re a professional builder or a weekend handyman, keeping your tools in top shape is essential to ensuring efficiency and safety. In this blog, we’ll discuss the signs that your power tools need repairs, where you can get them serviced and repaired and the benefits of regular maintenance.

Power Tool Repairs: Common signs

1. Reduced Performance or Power

When your power tool isn’t performing with its usual efficiency—whether it’s a drill that struggles to penetrate surfaces or a saw that cuts unevenly—it could signal deeper issues. This often stems from worn-out motor components, clogged air intakes, or dirt accumulation within the tool. Reduced performance not only slows down your projects but can also strain other internal parts, leading to costly repairs if ignored. Regular servicing can help maintain optimal performance and prolong the life of your tools.

2. Unusual Noises

Power tools are designed to operate smoothly, so any grinding, screeching, or rattling noise should raise a red flag. These unusual sounds often indicate internal wear, loose components, or damage to the motor or bearings. For example, a grinding sound could mean debris is caught in the gears, while screeching may point to a lack of lubrication. Catching these issues early with professional repairs can prevent further damage and restore your tool to its original quiet, efficient operation.

3. Overheating

Excessive heat during use is a warning sign that something isn’t right. Overheating can occur due to faulty wiring, worn-out brushes, or insufficient lubrication in the tool’s moving parts. Left unchecked, overheating not only affects the tool’s performance but can also lead to permanent damage, such as motor burnout. Ensuring proper ventilation and regular maintenance can help avoid this issue, while a quick repair may save you from having to replace the tool altogether.

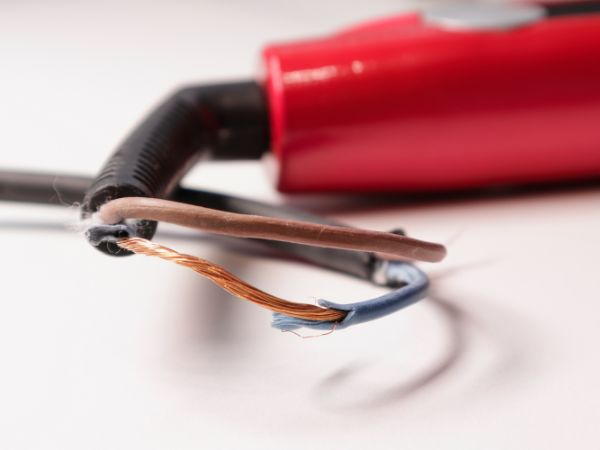

4. Power Lead Damage

A frayed or damaged power lead poses serious risks, from electrical shocks to reduced tool functionality. Many users rely on temporary fixes like electrical tape, but these are not safe or long-lasting solutions. A damaged power lead can disrupt the flow of electricity, causing inconsistent performance or even short circuits. Replacing the lead with a new one is a simple, cost-effective way to ensure safety and reliable operation. It’s always better to invest in a proper repair than risk an accident.

5. Inconsistent Operation

Erratic performance—such as tools that stop and start unexpectedly or fail to power on properly—is more than just an annoyance. It’s often a sign of deeper electrical issues, worn-out switches, or failing internal connections. Inconsistent operation not only slows down your work but could also lead to dangerous malfunctions. Seeking professional attention for these symptoms can prevent sudden breakdowns and keep your tools running smoothly, reducing the risk of injury or downtime.

6. Burning Smells

If you notice a distinct burning smell coming from your power tools, it’s often a sign of overheating or electrical issues. The smell could result from burnt wiring, overheated motor components, or a lack of proper lubrication in moving parts. Ignoring this warning sign can lead to serious damage and pose a safety hazard. Addressing the issue promptly with professional repairs can prevent further complications and ensure the tool operates safely.

7. Rust and Discolouration

Rust and discolouration on your power tools, particularly on metal components, indicate exposure to moisture or improper storage. Over time, rust can weaken the structure of your tools, reduce their efficiency, and cause mechanical parts to seize up. Regular cleaning and professional servicing can restore the tool’s condition and help protect it from further corrosion, extending its lifespan significantly.

Geographe Timber & Hardware: Power Tool Repairs in Busselton

- Expertise with All Major Brands Our in-house power tool repairs team is experienced with leading brands, including but not limited to: Metabo, Makita, Bosch and we are an agent for Milwaukee Repairs. We use genuine replacement parts, ensuring high-quality repairs and extending the life of your tools.

- Why Choose Local Sending tools to Perth or Bunbury can result in long wait times. We provide a faster turnaround, ensuring minimal downtime for your projects.

- Affordable and Transparent Service For peace of mind our experienced team will stay in contact with you while your job is ongoing. You’ll know exactly what to expect, with no surprises.

Benefits of Regular Maintenance for Your Power Tools

1. Improved Safety

Faulty tools can pose serious risks on-site. Regular maintenance ensures your tools are safe to operate.

2. Extended Lifespan

Routine servicing can prevent minor issues from escalating into costly repairs, ensuring your tools last longer.

3. Enhanced Productivity

Properly maintained tools operate at peak performance, helping you complete jobs more efficiently.

Expert Power Tool Repairs in Busselton

Does your favourite power tool need a bit of TLC? At Geographe Hardware, we provide onsite power tool repairs in Busselton and servicing for most power tools. Whether it’s a quick fix or a comprehensive repair, our experienced team is here to help. Visit us at 50 Gale Street, Busselton, or contact us via our website.

Final Thoughts

Regular maintenance and prompt repairs are crucial for keeping your power tools in optimal condition. Save yourself money, time and frustration by allowing our team to maintain your power tools.

FAQ: Power Tool Repairs at Geographe Timber & Hardware

Bosch

Makita

Milwaukee

Metabo

Hikoki

And many others!

We’re also an authorised service agent for warranty repairs on tools purchased from us.